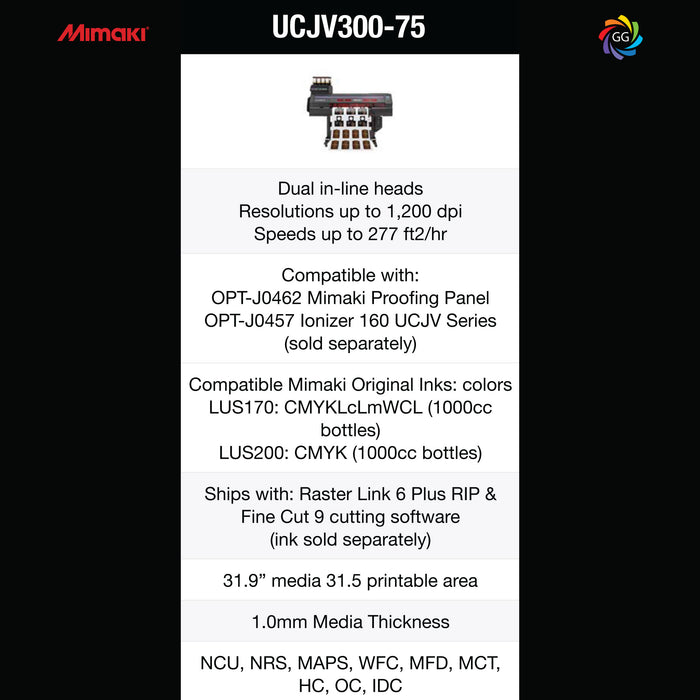

Mimaki UCJV300 Series - from $18,895 - Additional Fees May Apply

The UV-LED Printers Offer In-line Cutting Capability And Feature Layered Print Technology

The Mimaki UCJV300 series cut-and-print devices provide more than a simple print and cut experience: it goes beyond extraordinary to deliver an awe-inspiring range of applications and versatility. Create stunning transitional backlit panels that "change" color schemes with the light source. Print and cut or cut first then print labels, decals, window clings, vehicle markings, etc., all on one unit. Flexible UV cure inks expand the possibilities for you to offer unique capabilities to keep you competitive.

More Information

- Wide format, UV-LED cut-and-print devices

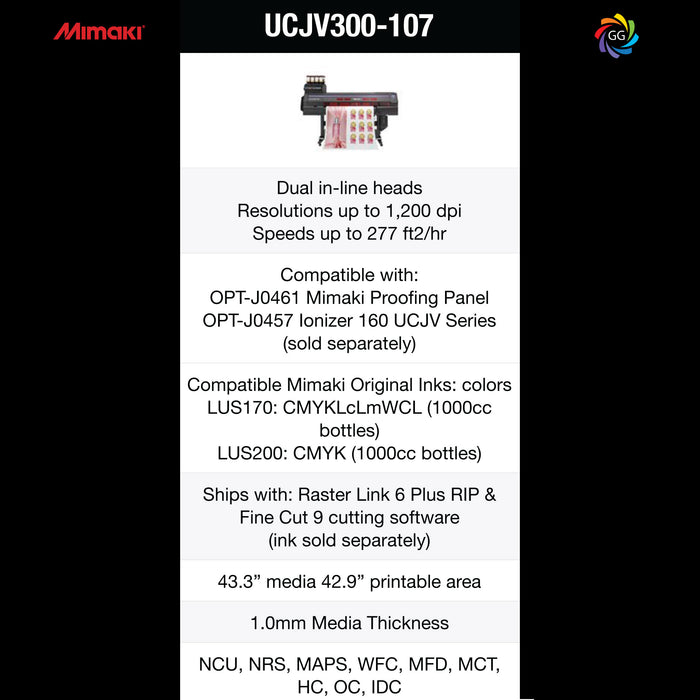

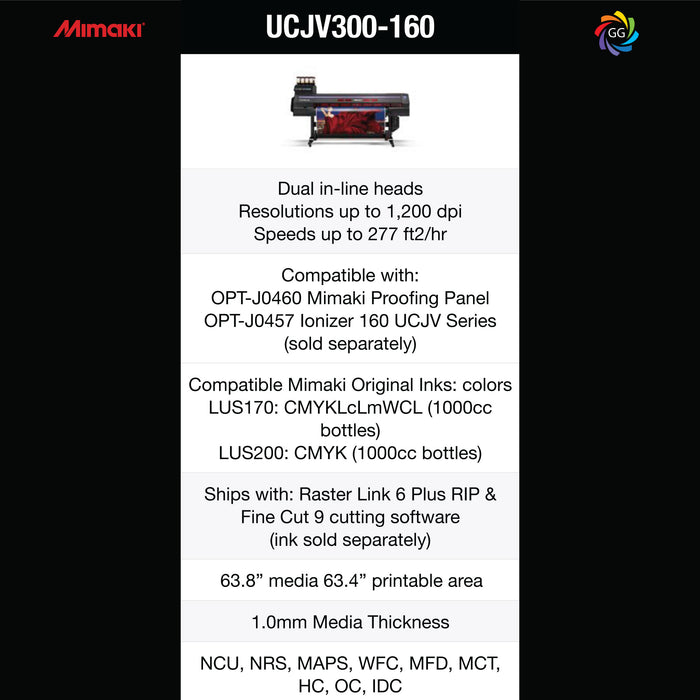

- 4 sizes available: 75, 107, 130 and 160 cm

- 4 or 7 color configuration

- Four-layer printing to build layered, transformative graphics for backlit applications

- Integrated cutting capabilities

- Instant-dry for instant use

- 1-liter ink bottles

Benefits

- Instantly cures and cuts

- Superior image quality on a wide array of media

- Odorless and reduces environmental impact

- GREENGUARD GOLD product certified for low emissions of VOCs

- No outgassing

- Low power consumption

- Low heat output

- Power efficient (uses 110v power)

- Uses non-solvent inks

- Ethernet and USB compatible

Highlights

-

Versatility in UV Roll-Based Printers

The UCJV300 series can produce a wide variety of applications, from backlits to window clings and nearly anything in between. UV-LED curing technology enables print service providers to use a wider range of media that may be too sensitive for latex or solvent systems that require heat to fix the ink.

One Graphic, Two Views

Four-layer printing color, black, white, color offers an enhanced print capability that allows designers to build layered transformative graphics for backlit applications. This gives you the opportunity to offer something unique a dynamic graphic that "changes" its image or color scheme depending on the light source. This distinctive capability means you can produce high impact, premium margin output while maintaining low operational costs and reducing production time.

Integrated Cutting Capability

The integrated cut functionality enables volume production of labels, decals, window clings, floor graphics, POP displays, vehicle markings, packaging and prototypes, and more in a single unit. Additionally, the ability to pre-cut before printing prevents common problems such as film separation and other issues related to post-cutting on thin materials.

Instant-Dry for Instant Use

UCJV300 series prints are instantly-cured at even the highest production speeds meaning you can quickly print and immediately move to finished product, unlike other technologies that require slower production to accommodate for dry time or out-gassing. For many jobs, instant-dry, durable, UV printing and cutting can also eliminate the need for additional finishing, so you can reduce time to sale while recognizing additional cost savings.

White Ink Adds Value

The combination of white and color inks available on the UCJV300 series adds value to applications utilizing transparent or semi-opaque films. Compared to alternative inks such as solvent and latex, UV-curable inks deliver greater opacity with less ink consumption per square foot of coverage while maintaining image vibrancy and density. High opacity white ink also enables block out printing within a single print, so you can easily and efficiently create window graphics that can be viewed differently from either side, as in a PUSH / PULL door sign. These features ensure higher throughput, reduced waste, perfectly registered double-sided graphics with lower overhead costs per print.

ID Cut Function in RasterLink6 Plus Software

The UCJV300 series will ship with updated RasterLink6 plus software that includes an ID Cut function to make printing and cutting easier and faster. Along with registration marks, RasterLink6 plus software will include a barcode on the print. The barcode, read by the crop mark sensor on the UCJV300 printer, contains cutting and rotation information allowing the UCJV300 printer to automate the cutting process. This function is particularly useful when running nested print-cut jobs, as the printer continuously reads the data for both single and ganged jobs.

Applications

- Backlit and day/night displays

- Signage

- Point-of-purchase displays

- Banners

- Posters

- Exhibition graphics

- Window clings

- Packaging

- and more!