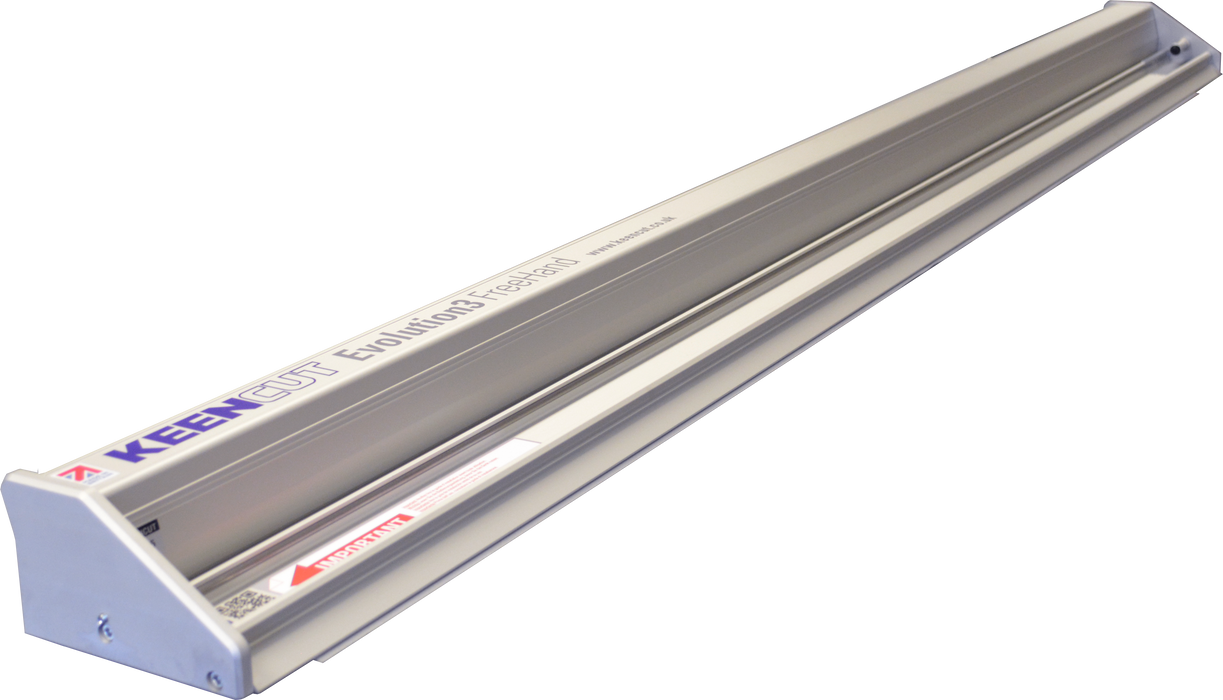

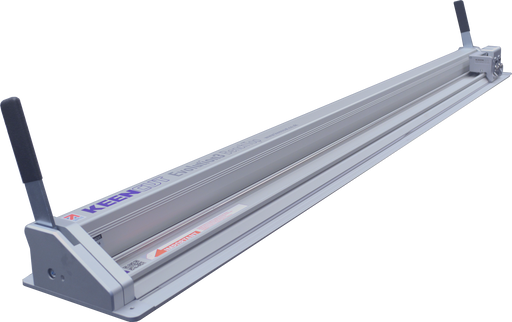

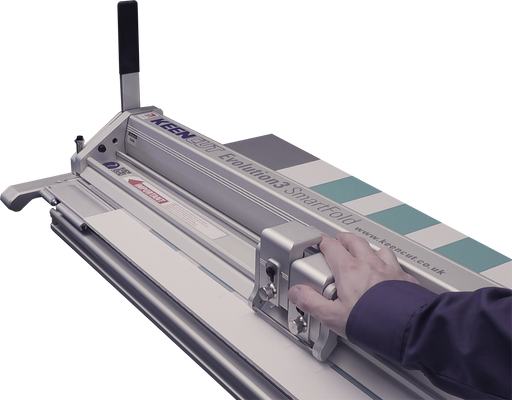

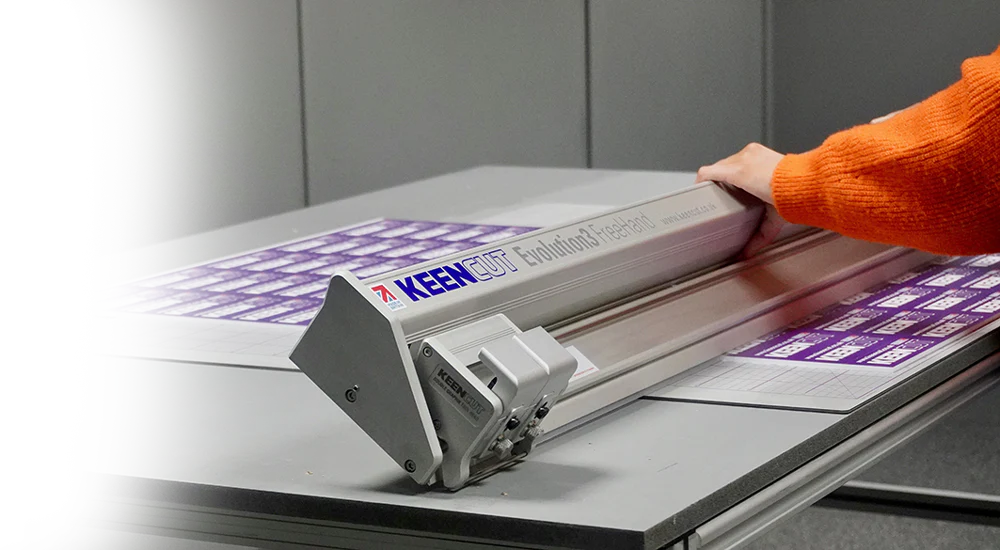

Keencut Evolution3 - FreeHand Series Cutter

The Evolution3 FreeHand has been designed for those who require the high precision accuracy and superior cutting quality of the Evolution3 range but in a more flexible format. It is perfect for a workshop where the cutter bar is required to move between workbenches. Evolution3 FreeHand gives you all the benefits of the QuikSwap cutting tools, sightline strip accuracy and anti-sag design in a portable cutter.

Keencut Evolution3 Range Brochure

Features:

Guaranteed accuracy

The Evolution3 is the most accurate cutter of its type on the market and is guaranteed to cut within 0.2mm (0.008″) of a straight line for the length of the cut. The in-built ultra-precision accuracy combined with the perfect alignment, made possible using the sightline strip, means every butt-jointed panel will join seamlessly. This ultra-precision accuracy will save you time and money with less waste and fewer mistakes.

Total stability

The self-adjusting track roller system fitted to the QuikSwap tool heads provides a strong and smooth movement up and down the length of the cutter bar, with zero sideways movement to ensure a perfect straight line. This, coupled with rigid blade clamping gives perfect blade control and spot-on accuracy, so less wastage and mistakes. On the FreeHand, the underside of the cutter bar has two silicone strips that will grip to the material surface preventing any chance of it slipping.

Simple to use

The ease of use makes it possible for even first time users to cut confidently and accurately with the Evolution3 FreeHand. The sightline strip guides you to achieve perfect accuracy and the heavy base and solid structure create a stable cutting platform.

Heavy duty reliability

The entire Evolution3 range has been built to last using high quality materials and well tested engineering principles. The cutting head bearing system guarantees perfect blade control even with the most difficult of materials. Keencut make the majority of components on its high-tech CNC machines keeping tolerances and quality under constant control, this assures exceptional accuracy and total reliability.

Future proof and versatile QuikSwap tool heads

The QuikSwap tool head family gives users the ultimate flexibility. Each tool is designed for a specific purpose, such as general cutting, creasing, fabric cutting and can be attached or detached from the cutter in seconds. You can mount single or multiple tool heads to suit your work and the Graphik tool head is supplied as standard with other optional QuikSwap tools available to extend your cutting capability. New tools are also being developed to meet emerging requirements.

The versatile Rocker head

The optional Rocker tool head is the latest addition to the QuikSwap range. It is a versatile general-purpose tool for cutting materials such as banners, cardboard and foamboard up to 10mm (3/8″). The ergonomic design follows the natural curvature of your hand and offers maximum comfort for every day, all day cutting. It also provides two-way cutting – pulling to cut lighter weight materials and pushing for those that require more effort.

Five year guarantee

Like all Keencut machines, the Evolution3 is precision built using top quality materials. All components are manufactured in-house to ensure quality and Evolution3 cutters come with a five year comprehensive guarantee. Register your product to activate your guarantee >

In the box

100 Graphik blades

Double Graphik tool head (mounted)

Materials cut

Semi-rigid materials

Corrugated cardboard ≤ 13mm (1/2″)

PVC foamboard ≤ 13mm (1/2″)

Corrugated plastic ≤ 13mm (1/2″)

Foam centred board ≤ 13mm (1/2″)

Rigid materials

Cast acrylic / Plexiglas ≤ 3mm (3/32″) scoring only

Flexible materials

Banners

Pop-ups

Magnetic sheets

Film

Self-adhesive vinyls