Mimaki TS55-1800 Dye-Sublimation

High Volume Dye-Sublimation Printer. Ultimate Scalability For Continuous Long-Run Printing.

This dye-sublimation transfer paper model is the future of digital textile printing. Effortlessly scale your operation with its high-end features that offer unattended continuous printing, industry-leading productivity and low running costs to meet marketplace demands.

Mimaki TS55-1800 Specification Sheet

More Information

- Maximum productivity of 1,453 sqft/hr

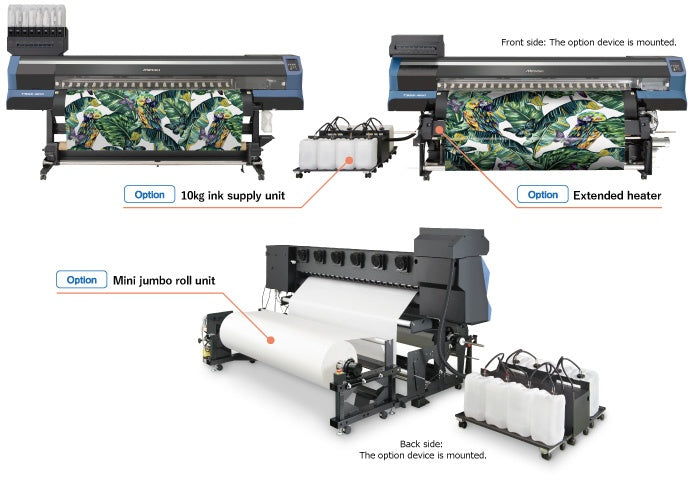

- Mini jumbo roll, 10kg ink supply and extended heater options for increased efficiency and lower costs

- Dye-sublimation inks available in 4, 6, and 8 color configurations, including fluorescent pink and yellow

- Ink holds ECO PASSPORT by Oeko-Tex® certification for safe and sustainable textile chemicals

- Upgraded with the newest TxLink4 textile RIP software

- RIP software RasterLink6 included

Benefits

- Waveform Control

- Variable Dot Technology

- Mimaki Advanced Pass System: The "MAPS" functionality providing gradation to printed pass boundaries maintains stable print quality by reducing banding and uneven color. The "TS55-1800" equipped with newly developed heads enables the "MAPS" in the high-speed mode, which has been unavailable so far. The technology allows the simultaneous pursuit of both high speed and high quality.

- Nozzle Check Unit: The Nozzle Check Unit (NCU) detects nonfunctioning nozzles and automatically cleans them. If the nozzles fail to operate after cleaning, defective nozzles are replaced by non-defective ones until a technician arrives, and printing is continued. This feature enables uninterrupted print operations and continuous productivity.

- Nozzle Recovery System: Fill the missing nozzles by enlarging the dots of the adjacent nozzles. *It gets missing nozzle stripes inconspicuous while printing by the Single-pass mode.

- Mimaki Bulk Ink System

- Mimaki Fine Diffusion

Highlights

-

Mini Jumbo Roll Unit

This is a feeding unit to load [Mimaki Vision Jet-X] transfer paper with a length of about 2,500m (8,202 ft). Reduces the cost per square meter and shortens the downtime due to media replacement in comparison to smaller transfer paper rolls.

22lb Ink Supply Unit

This has an ink supply unit to set a 10kg (22 lb) ink tank for a single color. Compared with the conventional 2L ink pack, the running cost is much reduced and the downtime due to ink replacement is shortened.

Extended Heater

This is an extended heater installed to the lower part of the standard heater. The heater enhances the ink-drying capability and prevents the "blocking" of medium (caused by still wet ink obstructing the feeding of the media during high-speed print), thus ensuring stable production.

Feed Correction Function by Print Mode

Different feed correction values can be applied to each print mode.

Feed correction value for each print mode can be managed by machine setting. It is not necessary to perform feed confirmation for every mode and reduces the work of operator.Variable Print Function Tailored to Applications for Apparel is Provided

Variable data such as uniform numbers and player names can be directly imported from CSV file to create print jobs. Text can also be processed using methods such as text outline fills and arched text layout.

Spot Color Inks

- Light black ink enables stunning gray-scale expression

- Because sublimation transfer print uses a high-density black ink, graininess or tone jump may occur in some cases. Light black ink adds to smooth print expression without graininess or tone jump.

- Fluorescent inks enable unique expression

-

The demand for fluorescent inks is rising in products such as uniforms and other sports apparel, fashion apparel representing Japanese cute pop culture, and eye-catching bright soft signage. To use fluorescent inks as the complementary colors of process colors, not to mention as spot colors, a multi-color mode (*) is provided. The fluorescent inks complement magenta and yellow to realize brighter colors.

* Only available in TxLink4

Applications

- Tapestry

- Flag

- Sports Apparel

- Interior Fabrics

- Fashion Textile